Categories

New products

-

Lens Ring Joint Gasket

Good quality Lens Ring Joint Gasket made by Chinese lead company Kaxite. Lens Ring Joint Gasket you can get with best price from us.

-

Double Jacket Gasket

Good quality Double Jacket Gasket made by Chinese lead company Kaxite. Double Jacket Gasket you can get with best price from us.

-

Stamping Jacket Gasket

Good quality Stamping Jacket Gasket made by Chinese lead company Kaxite. Stamping Jacket Gasket you can get with best price from us.

-

Corrugated Gaskets

Good quality Corrugated Gaskets made by Chinese lead company Kaxite. Corrugated Gaskets you can get with best price from us.

-

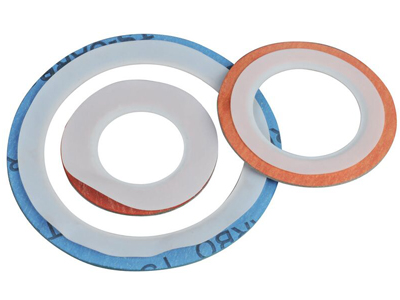

PTFE Envelope Gasket

Good quality PTFE Envelope Gasket made by Chinese lead company Kaxite. PTFE Envelope Gasket you can get with best price from us.

Non-Asbestos Jointing Sheets

Non-Asbestos Jointing Sheets are made of special non-asbestos heat-resisting Fibre, heat-resisting packing material, and special rubber compound heating and compression molding it.

|

|

KNXB200 Non-Asbestos Jointing Sheets |

|

KNXB300 Non-Asbestos Jointing Sheets |

|

|

KNXB350 Non-Asbestos Jointing Sheets |

|

KNNY150 Non-Asbestos Jointing Sheets |

|

|

KNNY250 Non-Asbestos Jointing Sheets |

|

KNNY300 Non-Asbestos Jointing Sheets |

|

|

KNNY350 Non-Asbestos Jointing Sheets |

|

|

|

Non-Asbestos Jointing Sheets are made of special non-asbestos heat-resisting Fibre, heat-resisting packing material, and special rubber compound heating and compression molding it. |

|||

|

|

|

Material: Made of special non-asbestos heat-resisting Fibre, heat-resisting packing material and nature rubber compound heating and compression molding it.

The other size is optional or according to the requirements of customers. |

|

Item |

KNXB200 |

KNXB300 |

KNXB350 |

KNNY150 |

KNNY250 |

KNNY300 |

KNNY350 |

|

Tensile strength MPa |

5.0 |

7.0 |

11.0 |

8.0 |

10.0 |

12.0 |

15.0 |

|

Aging Coefficient |

0.9 |

||||||

|

Density g/cm³ |

1.6 - 2.0 |

1.6 - 1.8 |

|||||

|

Compressibility % |

12 |

||||||

|

Rebound degree |

35 |

40 |

45 |

40 |

45 |

50 |

50 |

|

Pliability |

No Crack |

||||||

|

Stress-relaxation |

45 |

45 |

45 |

40 |

40 |

30 |

30 |

|

Oil sealing |

|

|

|

10 MPa pressure for 30 min |

12 MPa pressure for 30 min |

15MPa pressure for 30 min |

16 MPa pressure for 30 min |

|

With the temperature of 150 |

Tensile strength-reducing % |

40 |

30 |

25 |

25 |

||

|

Thickness-increasing % |

5-20 |

5-20 |

5-18 |

5-18 |

|||

|

Appearance change |

No bubble |

||||||

|

With the temperature |

Tensile strength MPa |

5 |

6 |

8 |

10 |

||

|

Thickness-increasing % |

5-25 |

5-25 |

5-20 |

5-20 |

|||

|

Pliability |

No Crack |

||||||